The universal sealing system for cable ducts, cable distributors,

cable service entries and ring space sealing.

Predestined in the field of power cables.

For duct ID Ø 40 - 300 mm.

Extended range of temperature-30°C to +45°C

(short-term +70°C/4h)

4 x usable.

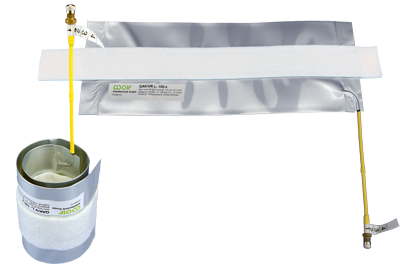

General information: QAK/V sealing cushion

ADE/V sealing elements with a valve (Fibre Optics CT patent, registered under EP 15154700.7) with petrolatum coating have been successfully used in practice since January 2006 and as a further development coated with swelling material for the extended temperature range for the use in the field of power cables for many years.

The sealing element (valve) fulfils the requirements of the T-Com TS 0307/96b (Approval No. Wolf 2005-08-11 ADE 100 (valve). Wolf sealing elements provide the user with a durable, reliable seal in a temperature range -30 °C to +45 °C (+70 °C for a short period of 4h).

The service life against reliable sealing of dust, smoke, noise and vibration, as well as up to 5 m water column and chemical mixtures pH2 to pH12 is > 20 years.

Sealing cushion materials :

The flat tube cushion is made of a five-layered aluminium laminate.

The high quality of both material and processing guarantees a very low diffusion/leak rate of ~ 0.73 mbarl / year and ensures a long service life.

The filling unit:

In order to be able to fill the sealing cushion several times (4 times), a patented metal air valve with a plastic-coated valve extension is connected to the sealing cushion by means of a heat-seal welding process.

The pressure is filled via a pressure hose, which is plugged onto the sealing cushion to fill the car valve. After the pressure has been filled, the valve is sealed pressure-tight with the valve cap.

Tight against gas diffusion, dust, water (5 m water column) and chemical mixtures

The high-quality, robust aluminium laminate …

adapts flexibly to the sealing area, independently of

cable diameter and configuration or contamination by dirtensures a long service life

is resistant to chemical mixtures pH2 to pH12, fuels etc.

Coated with swelling material product group WO 22.2 QV-DBK ...

- ensures tightness up to 0.5 bar/ 5 m water column immediately on contact with water

- ensures tightness against gas diffusion (volatile halogenated hydrocarbons in soil air < 100 mbar)

- allows quick, easy removal (< 2 min). No adhesion! Makes damage-free removal possible.

The patented car tyre valve construction …

- is simply inflated with compressed air (CO2-free!)

- makes on-site overpressure inflation technology simple

- allows flexible adaptation of the inflated cushion to fit the surrounding space and prevents buckling of cables and ducts or changes in technical transmission properties.

- Vermeidet Einbeulung von Kabeln und Rohren und Änderungen von übertragungstechnischen Eigenschaften.

- facilitates quick removal of air after cable retrofitting, by using accessory vacuum pump 33 VMSP or by changing the valve insert

- facilitates damage-free removal and re-installation

E-04.10_PB005_2005.pdfTotal leak rate/ Diffusion rate of sealing elements (valve) FO 04.10-PB 005/2005 (GEMTEC)564 KB

E-04.10_PB005_2005.pdfTotal leak rate/ Diffusion rate of sealing elements (valve) FO 04.10-PB 005/2005 (GEMTEC)564 KB E-04.30_PB175_2011.pdfResistance of reusable sealing systems to chemicals, petrol, diesel and leak detector agents FO 04.30-PB 175/2011 (TÜV - Süd)482 KB

E-04.30_PB175_2011.pdfResistance of reusable sealing systems to chemicals, petrol, diesel and leak detector agents FO 04.30-PB 175/2011 (TÜV - Süd)482 KB E-04.80_PB176_2011.pdfStorage life of reusable sealing elements with valve FO 04.80-PB 176/2011 (TÜV - Süd)494 KB

E-04.80_PB176_2011.pdfStorage life of reusable sealing elements with valve FO 04.80-PB 176/2011 (TÜV - Süd)494 KB E-04.90_PB179_2011.pdfBatch type test of reusable sealing elements (new valve design) FO 04.90-PB 179/2011 (TÜV - Süd)403 KB

E-04.90_PB179_2011.pdfBatch type test of reusable sealing elements (new valve design) FO 04.90-PB 179/2011 (TÜV - Süd)403 KB

E-04.110_PB178_2011.pdfAttenuation change in indoor and outdoor single-mode optical fibre cables due to lateral pressure FO 04.110-PB 178/2011 (TÜV - Süd)546 KB

E-04.110_PB178_2011.pdfAttenuation change in indoor and outdoor single-mode optical fibre cables due to lateral pressure FO 04.110-PB 178/2011 (TÜV - Süd)546 KB E-FO15_10-PB31_2012.pdfCost effectiveness of MaxCell multiple duct systems 4016-3 FO FO15.10-PB 31/2012501 KB

E-FO15_10-PB31_2012.pdfCost effectiveness of MaxCell multiple duct systems 4016-3 FO FO15.10-PB 31/2012501 KB