Filling-pressure monitoring system (during installation)

p-AK-MSBE Filling-pressure monitoring system with automatic regulation of

the filling pressure and power of p-joint-sealing cushions/V (valve) during installation.

Filling-pressure monitoring system with automatic regulation of the filling pressure and

power of p-joint-sealing cushions (valve) during installation (ceiling or wall mounting)

- For simple visual control during inspection and maintenance

- For controlling the target pressurefilling of 150 mbar to 300 mbar from below

General

The sealing efficiency and service lifetime of p-joint-sealing systems are directly related

to filling pressure, (which is temperature-dependent) and lateral movement along the x-axis.

It is therefore important to:

- adhere strictly to the installation specification, VO 60.02 Pressure-filling of Sealing Cushions with a Valve for Expansion and Movement Joints, and to provide proof of tightness.

- reach the permissible pressure filling for reusable p-seals for movement joints (type L: 300 – 350 mbar and type S: 150 – 200 mbar (20°C +10°C)) during installation. This can be achieved by using, for example, the filling-pressure monitoring system Art. No. 86.01 p-AK-MSMO.

- set up the filling-pressure monitoring system Art. No. 86.01 p-AK-MSMO for permanent regulation of filling pressure and power after installation (since pressure fluctuates as a consequence of movement along the X-axis in summer and winter, amongst other factors). Ceiling or wall Installation is recommended.

- carry out a visual inspection of the filling pressure (tightness) of the reusable p-seals for movement joints in the course of routine joint inspections, adjusting the filling-pressure where necessary.

Design:

Measuring element: Capsule spring,

CuBE alloy

Movement: Brass

Zero adjustment: From the front

Seal: NBR (perbunan)

Dial: Aluminium, white,

with black markings

Pointer: Aluminium, black

Housing: Stainless steel 304

Bayonet ring: Stainless steel 304

Window: Instrument glass

Panel-mounted devices

(types D 431/451)

Plastic (acryl

glass PMMA)

Technical specifications:

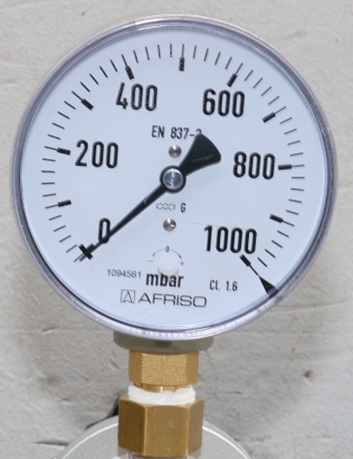

- Type D4

- Nominal size 100

- Accuracy class (EN 837-3/6): 1.6

- Display range (EN 837-3/5): NG 63-100

0/25 to 0/1000 mbar, and all corresponding

acuum and compound ranges with

over-pressure protection

- Application area:

Static load: full scale value

Dynamic load: 0.9 x full scale value

Overload safety: 1.3 x full scale value

Operating temperature range:

Medium: Tmax = +60°C

Ambient: Tmin = -20°C

Tmax = +60°C

Temperature performance:

Indication error when the temperature of the measuring system deviates from the normal temperature of +20°C:

Rising temperature approx. ± 0.6%/ 10 K

Falling temperature approx. ± 0.6%/ 10 K

of the full scale

Degree of protection: NG 63/160:

IP 33 (EN60529)

NG 100:

IP 54 (EN60529)

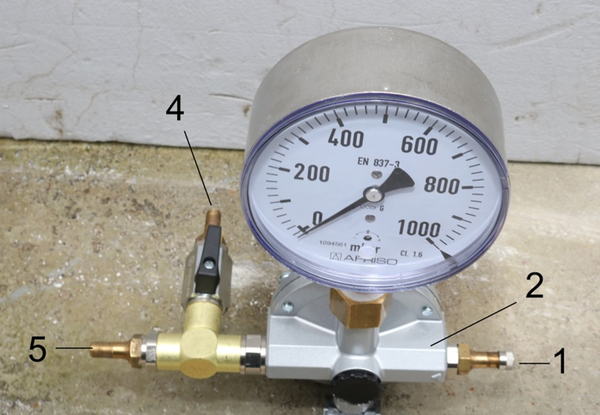

Key

p-AK-MSBE Filling pressure

indicator (for monitoring)

(For assembly unit: reusable

p-joint-sealing system)

1 Pressure inlet valve

2 Precision pressure controller

3 Pressure gauge Ø 100 mm 0–1000 mbar

4 Connection: pneumatic tubing for connection

to the reusable p-sealing system / valve

5.1 Where necessary, connection

(via pneumatic tubing) to

Art. No. 86.03 p-AK-GMA

Hazard alarm system

5.2 Pressure adjustment

(pressure inlet valve)

in the event of pressure loss

Type L < 300 - 350 mbar

Type S < 150 - 200 mbar

Note:

6 Mounting bracket

(for wall or ceiling attachment)

7 Rotary knob for pressure setting

(pressure setting fixed by means

of a locknut) is only used when

pressure filling takes place via

the pressure inlet valve (1)

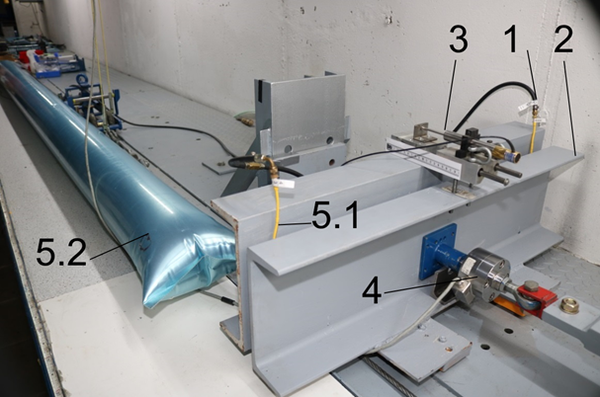

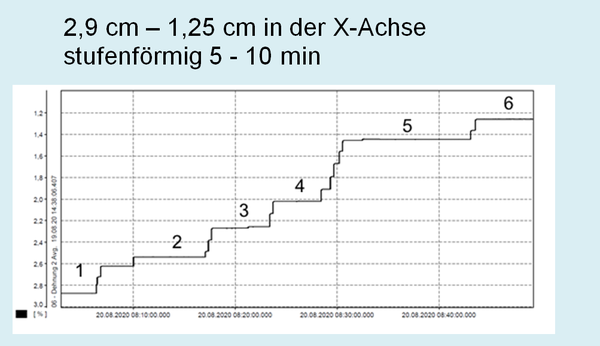

2. Functional example

(Fibre Optics CT GmbH test setup No. 3, Test Report 263/ 2020)

Test setup for

"Thermal resistance of the fully automatic monitoring system"

(Protocol No. 259 B/ 2020)

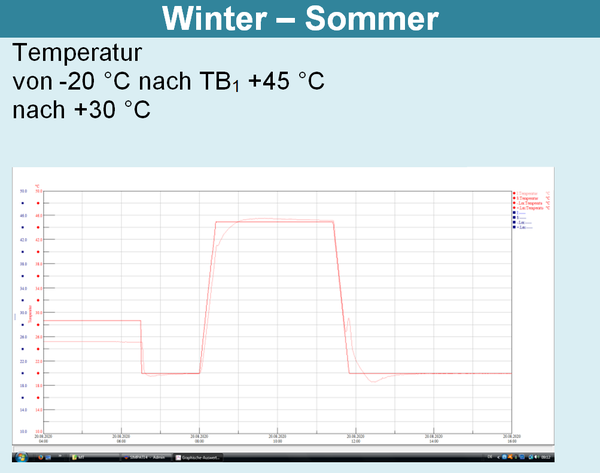

- Cycle 1:

At high temperatures TB1 +20 °C after +45 °C

+45 °C after +20 °C

stepwise lateral joint movements from 3 cm to 1.25 cm (narrowing),

at ambient temperatures acc. to "winter-summer hypothesis" after a dwell time of 24 h

- Cycle 2:

At low temperatures TA1 +20 °C after -5 °C

TA2 -5 °C after -30 °C

-30 °C after +20 °C

stepwise lateral joint movements from 3 cm to 6 cm (widening) and

back to 3 cm at ambient temperature acc. to "summer-winter hypothesis"

Procedure

Tests to establish the reliability of performance of the monitoring system (in controlling pressure-filling and monitoring) at high and low temperatures.

In the tests, the monitoring system unit and a container with water were placed in a climate chamber, to simulate actual operational conditions, in accordance with IEC 60068-2-14 section Nb (Fig. 1).

In operation, the monitoring unit is attached to the wall or joint edge and is connected to the sealing system by means of a pneumatic line.

The components are only used for the installation of the reusable p-seal and for the verification protocol of "sealing tightness and permissible filling-pressure", and are located outside the climate chamber.

Key

1 Movement-joint seal

2 Slideable weight to simulate lateral

deflection in the movement joint

3 Cylinder for measuring movement

4 Cylindrical pressure load cell

5 Test sample reusable p-seal,

uncoated

5.1 Test sample type L width bL 13.5 cm,

length lV 74 cm

Movement at temperature (20 ± 5 °C)

5.2 Test sample type S width bL 28.5 cm,

length lV 409 cm

Without movement

![[Translate to English:] Durchflusscharakteristik Präzisionsdruckregler](/fileadmin/user_upload/Icons/86-2_Durchflusscharakteristik_Praezisionsdruckregler.png)

![[Translate to English:] Hysterese Präzisionsdruckregler](/fileadmin/user_upload/Icons/86-2_Hysterese_Praezisionsdruckregler.png)

![[Translate to English:] Fülldruck Monitoringsystem](/fileadmin/_processed_/b/a/csm_Fuelldruck_Monitoringsystem_Ansicht_von_oben_f5c4f28360.png)