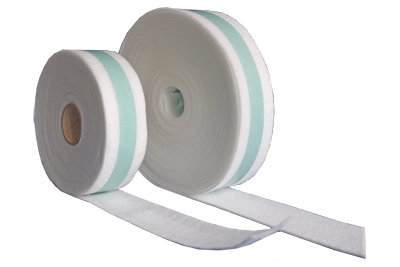

Self-sealing, nonwoven swelling material, consisting of mechani-cally preprocessed, heat-fixed, fibre-bonded material made of PP fibres and special super- waterabsorbent fibres, UV-stabilised.

Geotextile robustness class TL Geok EStB05-3

Applications: QV-DBK swelling sealing tape

Self-adhesive swelling tape QV-DBK consists of swelling sealing tape Article No. WO22.1 QV-DB manufactured with double-sided adhesive tape on one side.

Application:

- For sealing cushions and cable sealing

For example when petrolatum-vaseline tapes or old swelling tapes are replaced in the course of refurbishing sealing elements.

QAK/V sealing elements are more suitable (WO16) for service entries in buildings, in the areas of FTTH, photovoltaic, wind energy or bio-gas facilities etc, where a grease-free seal (no dripping oil etc.) is required within the temperature range.

QV-Seal water blocking layer are preferable for applications where requirements demand low weight and high resistance to cuts and burst pressure.

Product range:

Art. No. Sizes Length | Dimensions [mm] |

22.2 QV-DBK (1) 2.0 x 50/ 10 | 2.0 x 50 |

22.2 QV-DBK (2) 4.2 x 135/ 10 | 4.2 x 135 |

22.2 QV-DBK (2) 4.2 x 50/ 10 | 4.2 x 50 |

* Special size, not kept in stock on a regular basis - available on request.

(1) 2,0 = 200 g/m² (2) 4.2 = 480 g/m²

Technical data:

Swelling fleece:

Geotextile robustness class TL Geok EstB 05 | 3 GRK |

Weight per unit area dry/swollen/ dry EN ISO 9864 | 450/ 8200/ 435 g/m² |

Thickness EN ISO 10319 wet/ dry 2 kPa | 2.2/ 9.5/ 4.2 mm |

Porosity |

< 3.0 x 10-9 m/s < 3.9 x 10-9 m/s |

Static puncture resistance |

|

Swelling pressure | ca. 170 kN/m² |

Penetration test Damage (pierced hole) Ø 5 mm: unpressurised circular diffusion < 1 cm | |

Resistance | DIN EN Test standard |

| 14030:2003-11 |

12224: 2000-11 | |

12225:2000-12 | |

13438:2005-02 | |

12447:2002-03 | |